Handling Production Shrinkages using SAP Business ByDesign

Production shrinkages refers to the loss of materials or products during manufacturing.

In order to deal with production shrinkages/losses within SAP Business ByDesign there are a few options that can be used:

Increase the quantities of the input materials in the Bill of Materials that have losses to include the estimated loss, for example increase input material 1 from 10kg to 10.3kg. You keep the output quantity the same.

This has the advantage that the production task confirmation, if using backflush, will already have the expected losses included and the cost of production in the material cost estimate correctly includes the expected losses of input product. It also allows you to finely control which input materials incur the loss and so need quantities increasing.

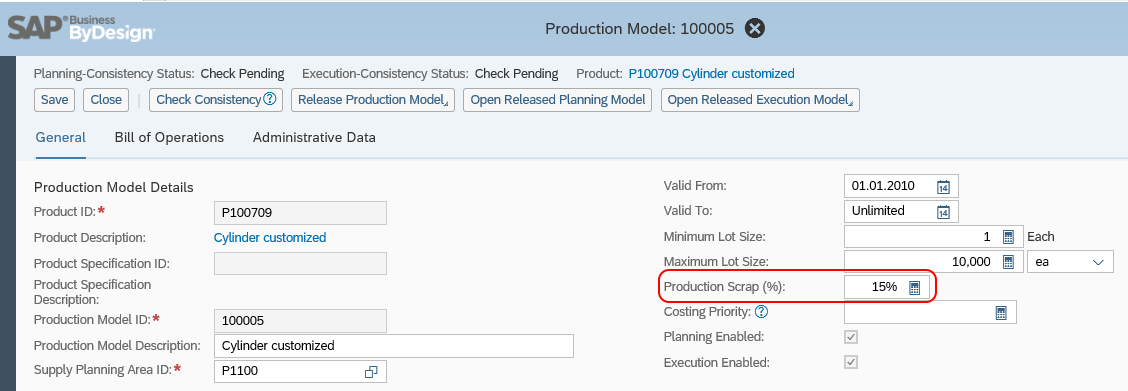

Add scrap percentage to the Production Model

This method will increase the requested input products equally across all lines by the percentage scrap set. This means that you cannot control which input materials are actually lost and if you are using units of measure that have no decimal places, for example EACHES, then the system will round up. For example, you have an input line for one container, with a scrap percentage of 10%. The system will then request two containers as it rounds up 1 Container x 10% scrap = 1.1 containers which is then rounded up to 2 containers.

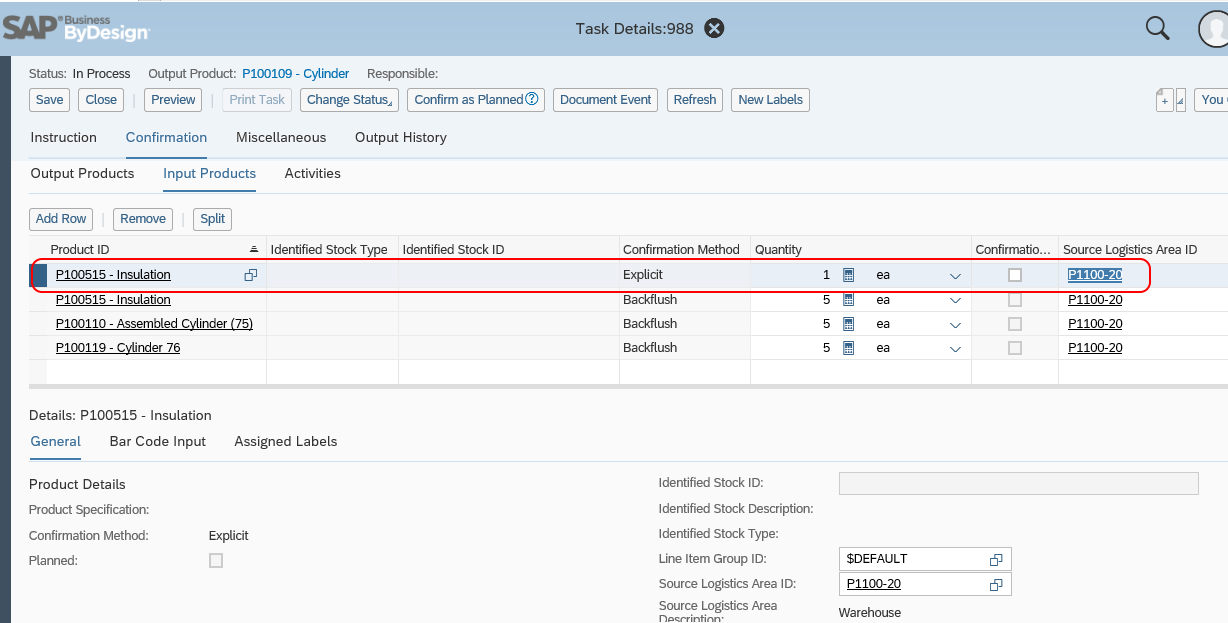

Add additional input product lines to the production task confirmation for the lost material

This is similar to the option of amending the Bill of Materials to increase input material quantities, but instead you add the additional lost quantities to the production confirmation as an explicit confirmation. The disadvantage of this is that you need to enter these values manually so can be time-consuming.

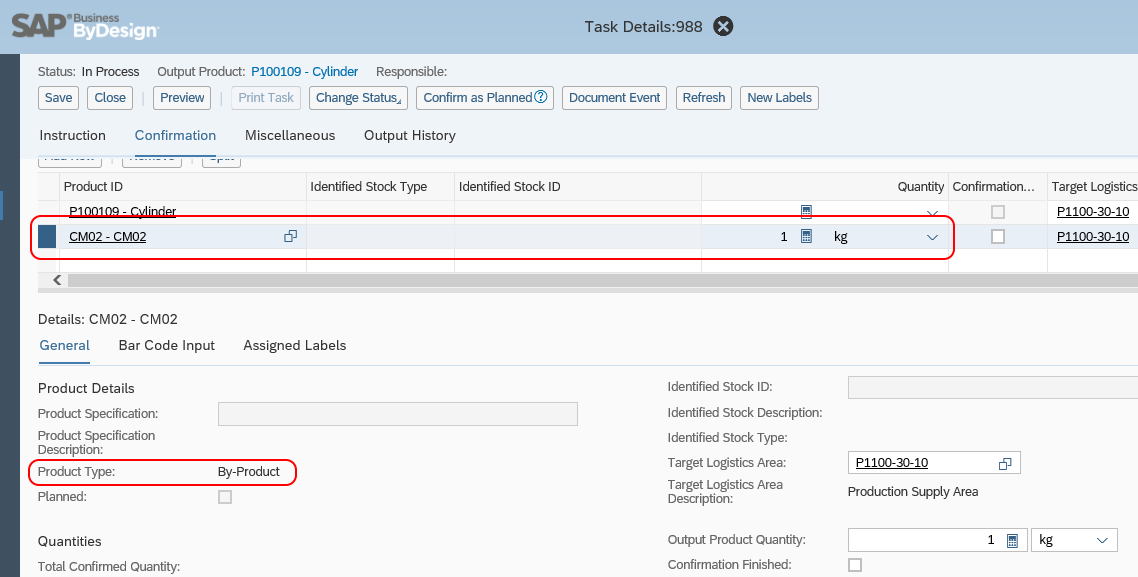

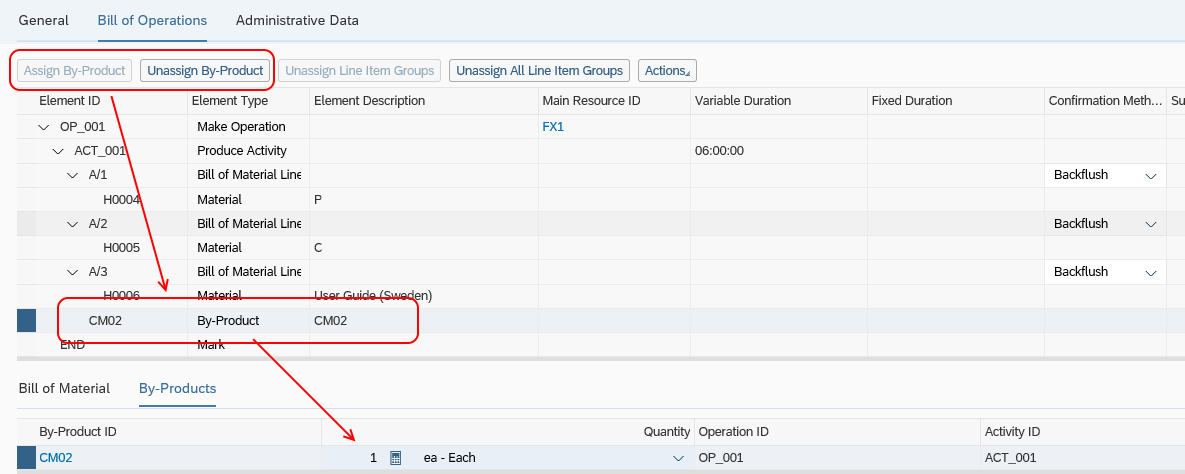

Use By-Products on production output which are then scrapped

In this method you either add an additional output by-product on the production task confirmation or include it within the production model. The output by-product goes into inventory on completion of the production task confirmation and the by-product can then be scrapped. This option allows for waste product that is created to be scrapped or reprocessed in other processes, but also allows for posting the scrapped material costs into the relevant G/L code. It does add an extra step to the process as the waste materials need to be scrapped. You should also consider that by-products are not considered in WIP runs - please see SAP support case note 2058109.

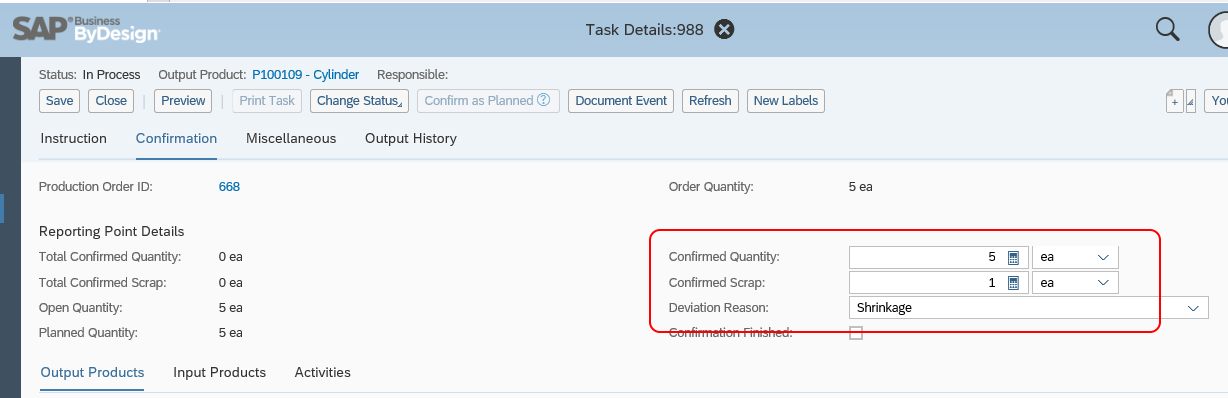

Add confirmed scrap quantity on the production confirmation

When completing the production task confirmation you can add a scrap quantity. This scrap quantity will increase the input product quantities automatically based on the total produced amount (Confirmed Quantity + Confirmed Scrap). One advantage here is that you can record a reason code (which can be customised) but if you want to have multiple reason codes entered you will need to save multiple task confirmations.